Description

Case 1 New Energy Battery Grinder

Applicable scope: one-time completion of new energy battery welding melting point polishing and deburring process, man machine interface PLC programming control, one-key start. Machine hand feeding and unloading, can be docked with the overall production line.

Case 2 Round pipe (bar) chamfering machine

Main technical parameters: R-angle case

Applicable scope: Sawing edge and chamfering R/flat angle at both ends of various bar pipe fittings, adjustable R5-25, automatic feeding and unloading, and can be connected with the whole production line for production. Range workpiece diameter 5-300 optional, length 50-2000 optional.) Man-machine interface control, one key to start the operation of the complete set of equipment;

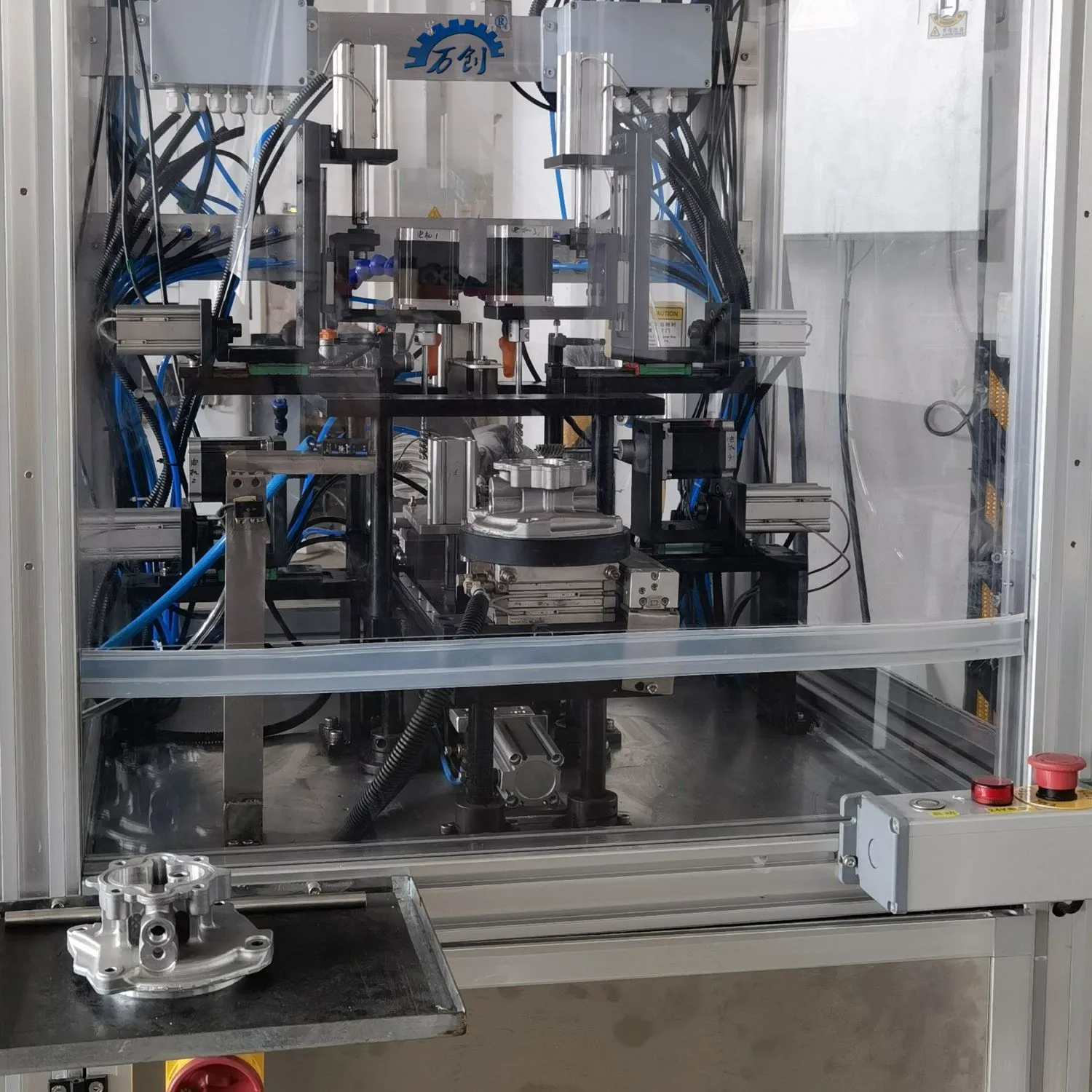

Case 3 Automated deburring machine for inner cross hole

Applicable scope: It is applicable to deburring process for cross-hole and inner-hole burr of work pieces such as oil pump valve body and hydraulic cylinder. Compared with high-pressure water and fluid deburring, it has higher deburring efficiency, better deburring effect, more energy-saving and environmental protection, and lower cost of equipment. Machine hand feeding and unloading, man-machine interface PLC programming control, one key start.

Case 4 Visual inspection equipment

Applicable scope: It is suitable for sorting of product appearance defect detection (such as scratches, bumps, stains, burr residues, etc.) instead of manual visual inspection, which is more efficient and accurate than manual inspection. It can be connected with other production equipment online detection, man-machine interface PLC programming control, one key start.

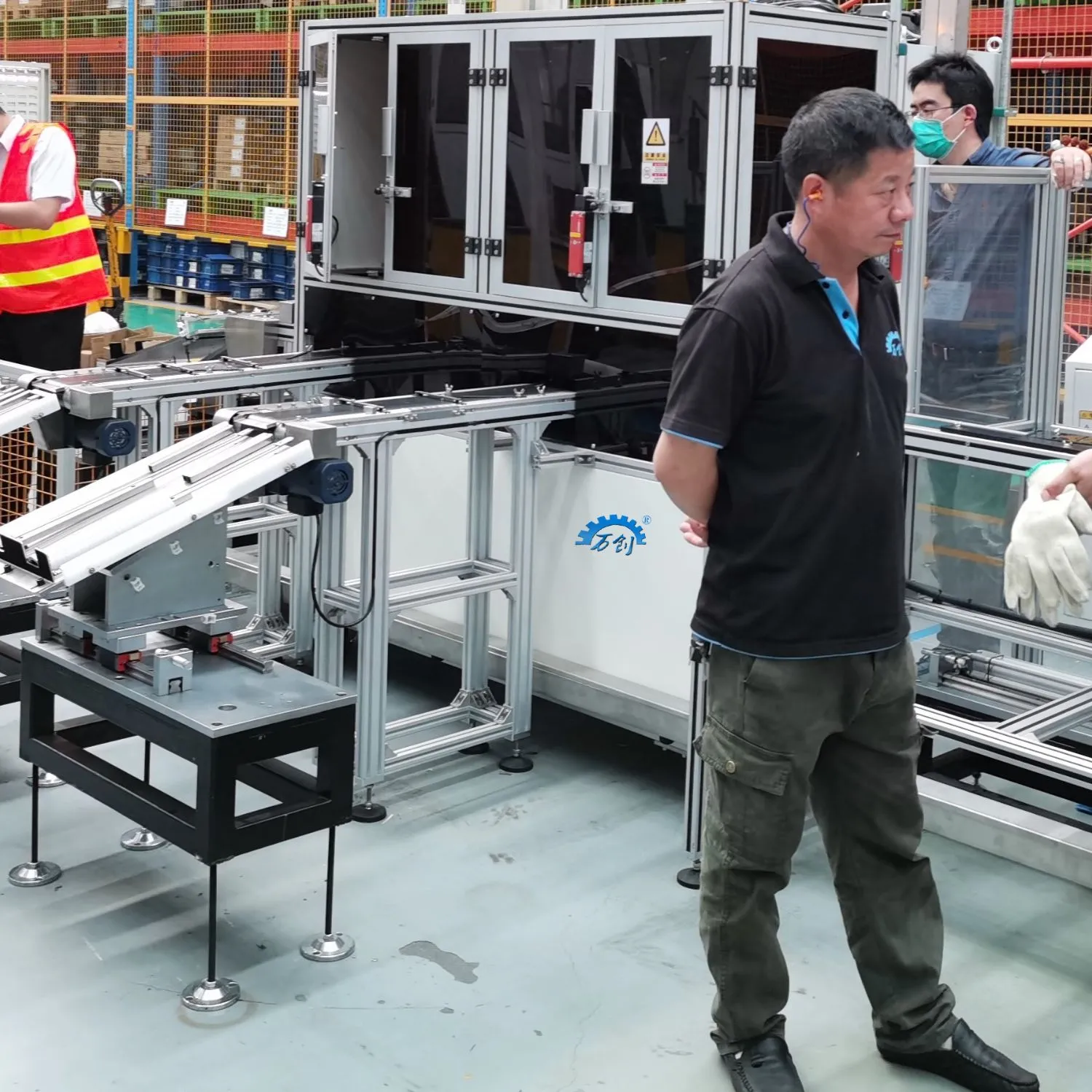

Other Application Cases