Description

Product Parameters

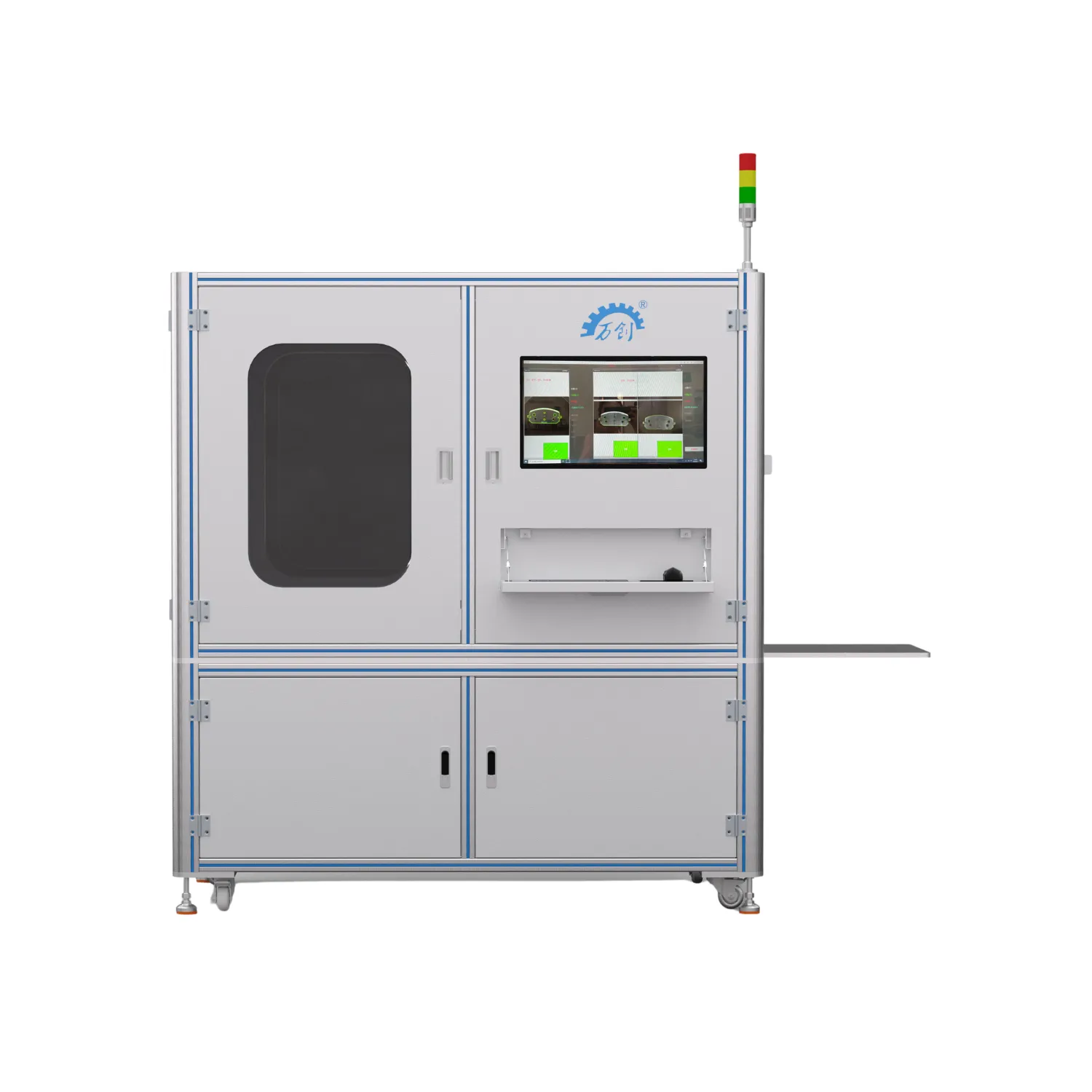

- The entire production line, including the feeding, conveying, inspection, and defective product removal systems, is controlled by PLC programming, allowing for one-button start and stop.

- A touchscreen human-machine interface with a three-core two-phase power supply and a stable 220V voltage. It features multiple safety protections, including fault warning lights, a safety grounding wire, overload protection, door-opening power-off, and an emergency stop switch. Numerous safety signs ensure operator safety.

- A fully Chinese operating system allows for one-button or manual start modes. System parameters (such as conveyor speed and product configuration parameters) can be modified and saved. The system includes fault monitoring and alarm functions, and running time statistics. The PLC reserves more than 15% of spare points for future integration with other upstream and downstream equipment, enabling coordinated control of the entire plant.

- Protective covers and an automatic lubrication system are installed on the equipment’s gears, sliders, guide rails, and lead screws to ensure long-term stable operation. The equipment’s inspection areas are enclosed and equipped with lighting, making the workflow visible.

Scope Of Application

Detects excess material, insufficient material, deformation, mixed materials, and mixed batch numbers in stamping processes. Utilizes AI algorithms and intelligent self-learning, achieving 100% recognition rate. Customization is available to add a module for detecting external dimensions.