Deburring is a critical process in metal part manufacturing. Different deburring methods are suitable for different product structures, burr sizes, and production volumes. Below are ten commonly used deburring methods in industrial applications.

1. Manual Deburring

This is the most widely used method in general manufacturing. Files, sandpaper, and grinding heads are used as auxiliary tools, including manual filing and pneumatic grinding.

Manual deburring involves high labor costs and relatively low efficiency. It is difficult to remove burrs in complex cross holes, but it does not require highly skilled operators. This method is suitable for parts with small burrs and simple structures.

2. Stamping Die Deburring

Deburring is carried out using punching dies installed on a press machine. Mold manufacturing involves certain costs (rough dies and fine dies), and in some cases, forming dies are also required.

This method is suitable for parts with simple parting surfaces and offers higher efficiency and better deburring results compared to manual deburring.

3. Grinding and Abrasive Deburring

This category includes magnetic deburring, vibratory deburring, sandblasting, and tumbling deburring, which are widely used in mass production.

However, burr removal may not be completely thorough, and secondary manual processing or additional deburring methods may be required. It is mainly suitable for large batches of small parts.

4. Cryogenic Deburring

In this process, burrs are rapidly embrittled by extreme cooling and then removed by blasting.

It is suitable for parts with thin burr walls and small-sized components.

5. Thermal Explosion Deburring

Also known as thermal deburring or explosive deburring, this method introduces a controlled amount of natural gas into a sealed chamber, where it ignites instantly under specific conditions. The released energy dissolves and removes burrs.

This process requires advanced operational expertise, has relatively low efficiency, and may cause side effects such as rusting or deformation. It is mainly used for high-precision components.

6. Engraving Machine Deburring

The equipment cost is relatively low and is suitable for parts with simple spatial structures and regular deburring positions.

7. Chemical Deburring

Based on electrochemical reaction principles, chemical deburring selectively removes burrs from metal parts automatically.

It is suitable for hard-to-reach internal burrs and small burrs on components such as pump bodies and valve bodies (burr thickness less than 0.07 mm).

8. Electrochemical Deburring (ECD)

Electrochemical deburring is a metal processing method that removes burrs through electrochemical reactions. The electrolyte is corrosive, and areas near the burrs are also affected, which may reduce surface gloss and affect dimensional accuracy.

After deburring, workpieces must be thoroughly cleaned and protected against rust.

ECD is suitable for concealed or complex-shaped parts and offers high production efficiency, with deburring times ranging from a few seconds to several tens of seconds. Typical applications include gears, connecting rods, valve bodies, crankshaft oil passages, and edge rounding.

9. High-Pressure Water Jet Deburring

Using water as the processing medium, burrs and flash generated during machining are removed by instantaneous high-impact water jets, while simultaneously cleaning the workpiece.

10. Ultrasonic Deburring

Ultrasonic deburring machines generate instantaneous high pressure to remove burrs.

This method is mainly used for extremely fine burrs that often require microscopic observation and precision removal.

One-Stop Automated Polishing and Grinding Solutions

Vantrn (Suzhou) Ai Machinery Co., Ltd provides comprehensive one-stop solutions for automated polishing and grinding equipment, including:

- Loading and unloading robotic manipulators

- Material handling and logistics conveying systems

- Polishing and grinding equipment

- Cleaning and drying systems

- Oiling equipment

- Water filtration and dust removal systems

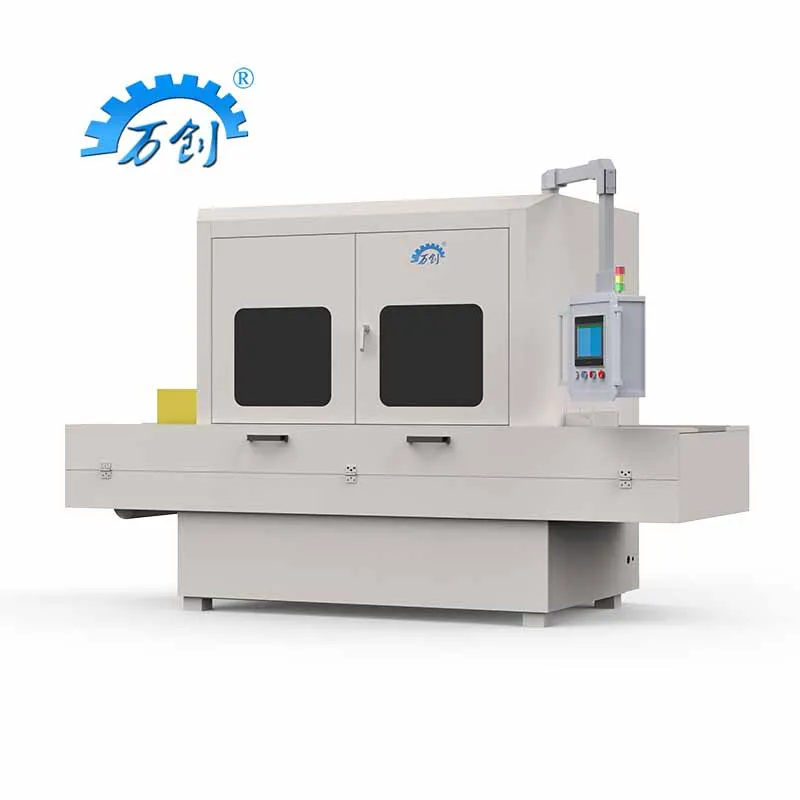

Our product range includes automatic deburring machines, belt brushing machines, and deburring systems for irregular-shaped workpieces.

We also offer customized services such as non-standard automated polishing and grinding machines, complete polishing and grinding production lines, and full-factory industrial automation design, manufacturing, and upgrading solutions. With complete pre-sales, in-sales, and after-sales support, we welcome both new and existing customers to contact us for consultation and cooperation.